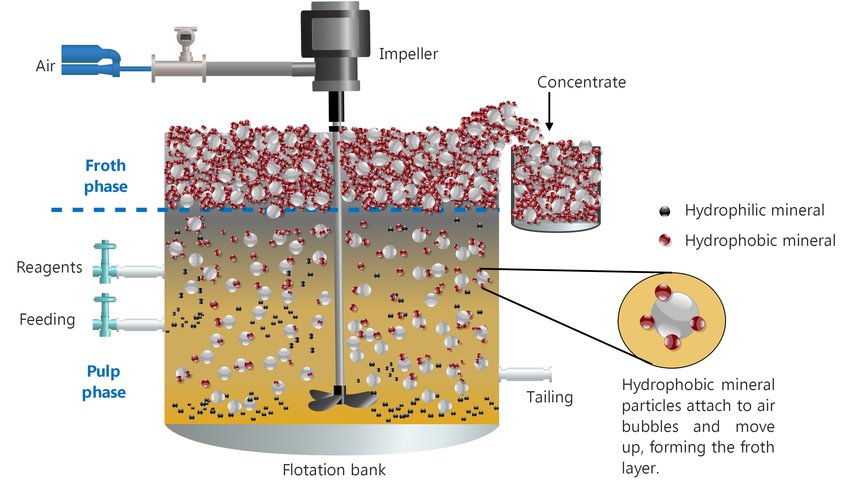

Flotation is a critical separation method used in ore beneficiation. However, many operations suffer from inefficiencies due to recurring errors in flotation plant design and operation. Here are the top five common mistakes:

- Improper Pulp Density Adjustment

Operating with pulp that is too diluted or too dense disrupts particle-bubble interaction and reduces recovery rates. - Inadequate Aeration Control

Over or under-aeration negatively impacts froth stability and selectivity in mineral separation. - Neglecting Reagent Optimization

Using outdated dosages or unsuitable reagents causes poor selectivity and increased operational costs. - Uncalibrated Level Control Systems

Incorrect froth height affects residence time and leads to inconsistent product quality. - Lack of Maintenance on Critical Equipment

Components like impellers, stators, and air injectors require periodic checks to avoid performance loss.

💡 With Minevate’s technical analysis services, you can avoid these common pitfalls and improve your flotation efficiency by up to 40%.