The Best Service for Your Industry, with a Strong Partner by Your Side

Crushing Equipment

Optimize your mining operations with our high-performance and durable crushing equipment. Engineered for reliability and efficiency, our crushers ensure maximum productivity and long service life in demanding mining environments.

Screening Systems

Enhance process efficiency with our advanced screening systems, specially designed for effective separation and classification. Our screening solutions improve material handling and contribute to optimized mining workflows.

Conveyor Systems

Ensure seamless material flow with our reliable conveyor systems. Designed for continuous operation, our conveyors increase productivity and reduce downtime in mining material handling processes.

Spare Parts and Consumables

Discover high-quality spare parts and consumables designed to extend the lifespan of your mining equipment. Our reliable components ensure optimal performance and minimize downtime, supporting sustainable and efficient mining operations.

Tailor-Made Solutions for Your Facility

Every facility has unique needs. At Minevate, we analyze site data and operational workflows to develop efficient and cost-effective custom solutions. This ensures maximum performance at every stage of your production process.

On-Site Visits

Our professional team conducts on-site visits to closely support your operations and provide tailored improvement recommendations.

The Minevate Difference in Mining

Our crushing and screening equipment, engineered for high efficiency, durability, and robust performance, offers tailored solutions for diverse mining processes.

At Minevate, we cater to the needs of operations of all sizes with a wide product range—from jaw crushers to cone crushers, and from vibrating screens to rotary screens. Tested on-site and designed for energy efficiency and sustainability, our solutions enhance performance across the mining sector.

- Jaw Crusher

- Impact Crusher

- Cone Crusher

- Tertiary Crusher

- Vibrating Screen

- Trommel Screen

- Grizzly Screen

- Belt Conveyor

- Spare Parts and Comsuables

Technical Specifications

Jaw Crusher

Application:

Ideal for primary crushing of large-sized ores and rocks in mining and quarrying operations.

Advantages:

- High crushing capacity

- Robust and reliable design

- Easy maintenance and operation

Technical Specifications:

- Crushing Opening: 100 mm – 1500 mm

- Motor Power: 30 kW – 250 kW

- Processing Capacity: 1 – 500 tons/hour

Primary Impact Crusher

Application:

Designed for high-performance breaking of large materials in mining and construction sectors.

Advantages:

- Excellent energy efficiency

- Low wear and maintenance cost

- Modular design for easy installation

Technical Specifications:

- Crushing Opening: 200 mm – 1300 mm

- Motor Power: 75 kW – 300 kW

- Processing Capacity: 20 – 600 tons/hour

Secondary Impact Crusher

Application:

Ideal for further size reduction after primary crushing, producing finer and more uniform materials.

Advantages:

- Consistent and homogeneous output

- High efficiency

- Fast replacement of wear parts

Technical Specifications:

- Crushing Opening: 50 mm – 700 mm

- Motor Power: 37 kW – 200 kW

- Processing Capacity: 10 – 400 tons/hour

Vertical Shaft Impact Crusher (VSI)

Application:

Perfect for fine crushing and shaping applications, especially in aggregate production and concrete manufacturing.

Advantages:

- Superior shaping capability

- Minimal dust and fine output

- Adjustable crushing parameters

Technical Specifications:

- Crushing Opening: 0 – 30 mm

- Motor Power: 45 kW – 250 kW

- Processing Capacity: 5 – 300 tons/hour

Tertiary Crusher

Application:

Used in the final crushing stage to achieve precise particle sizes and high-quality end products.

Advantages:

- Fine crushing capability

- High product quality

- Strong wear resistance

Technical Specifications:

- Crushing Opening: 10 mm – 50 mm

- Motor Power: 30 kW – 150 kW

- Processing Capacity: 5 – 200 tons/hour

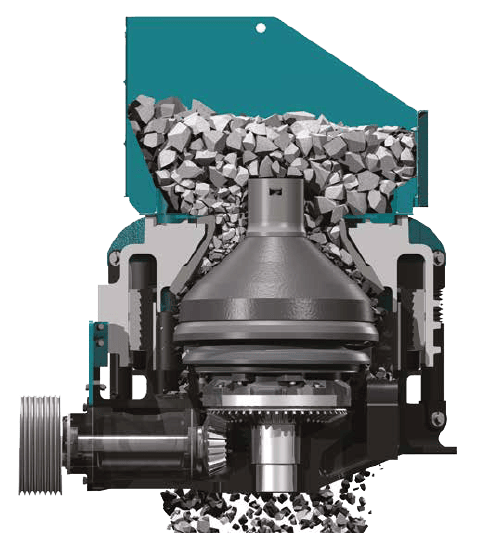

Cone Crusher

Application:

Designed for medium to fine crushing of hard and abrasive materials in mining and aggregate production.

Advantages:

- High crushing ratio

- Energy-efficient performance

- Low maintenance and long service life

Technical Specifications:

- Crushing Opening: 50 mm – 250 mm

- Motor Power: 75 kW – 350 kW

- Processing Capacity: 10 – 700 tons/hour

Vibratory Screen

Description:

Vibratory screens utilize high-frequency vibrations to separate materials based on particle size. As materials move across the screen surface, smaller particles pass through while larger ones remain on top. Commonly used in mining, construction, and recycling industries, these screens offer high throughput and precise classification.

Advantages:

- Adjustable vibration amplitude and frequency

- Suitable for both wet and dry materials

- Low maintenance and durable construction

Rotary Screen

Description:

Rotary or trommel screens classify materials through a rotating cylindrical drum. Smaller particles fall through perforations while larger ones are retained and separated. These systems are widely used in composting, wastewater treatment, agriculture, and mining.

Advantages:

- Efficient screening in bulk operations

- Simple installation and minimal maintenance

- Robust performance in harsh conditions

Grizzly Screen

Description:

Grizzly screens feature a rugged bar or grid structure that separates oversized materials before the main processing stage. Ideal for heavy-duty pre-screening in mining and quarrying, these screens prevent equipment overload and improve process efficiency.

Advantages:

- Heavy-duty construction for extreme environments

- Fast and easy maintenance

Enhances crusher lifespan by pre-screening large materials

Our Services

Manufacturing of Crushing and Screening Equipment

We design and locally manufacture highly durable crushing and screening systems tailored to your operational needs.Mining Machinery and Solutions

We develop and implement machine solutions that enhance efficiency, customized for your mining operations.Supply of Spare Parts and Consumables

We ensure uninterrupted equipment operation by supplying original, high-quality spare parts and consumables.Technical Engineering Services

Our expert engineering team provides comprehensive technical support, from project design to on-site implementation.Energy Efficiency and Performance Optimization

We offer solutions that minimize energy consumption and improve the performance of your equipment.On-Site Testing and Quality Control

We guarantee our quality and performance standards by conducting field tests on our equipment.Global-Scale Partnerships

We provide services at international standards by establishing strong collaborations with our global partners.

Reliable Mining Solutions Start with the Right Partner

At Minevate, we develop long-lasting, engineering-driven solutions by understanding real field requirements. We’re here to help you select the most suitable equipment for your plant and move your mining projects forward with confidence.

Contact us today and start making a difference in your mining operations.